KITECH KAMIC - Daegyeong Center

Introduction

Daegu-Gyeongbuk KITECH KAMIC has conducted extensive research to enhance the industrial value of 3D printing technology. The center has achieved significant results in various fields of metal materials engineering, including mold manufacturing with improved wear resistance using 3D printing hardfacing technology for high-hardness, heat-resistant alloy materials, additive manufacturing of gas turbine combustion chamber components using Ni-based superalloy materials, and the localization of powder materials. Additionally, the center has developed additive manufacturing processes for copper alloy materials, applying them to the production of induction motors and heat treatment coils.

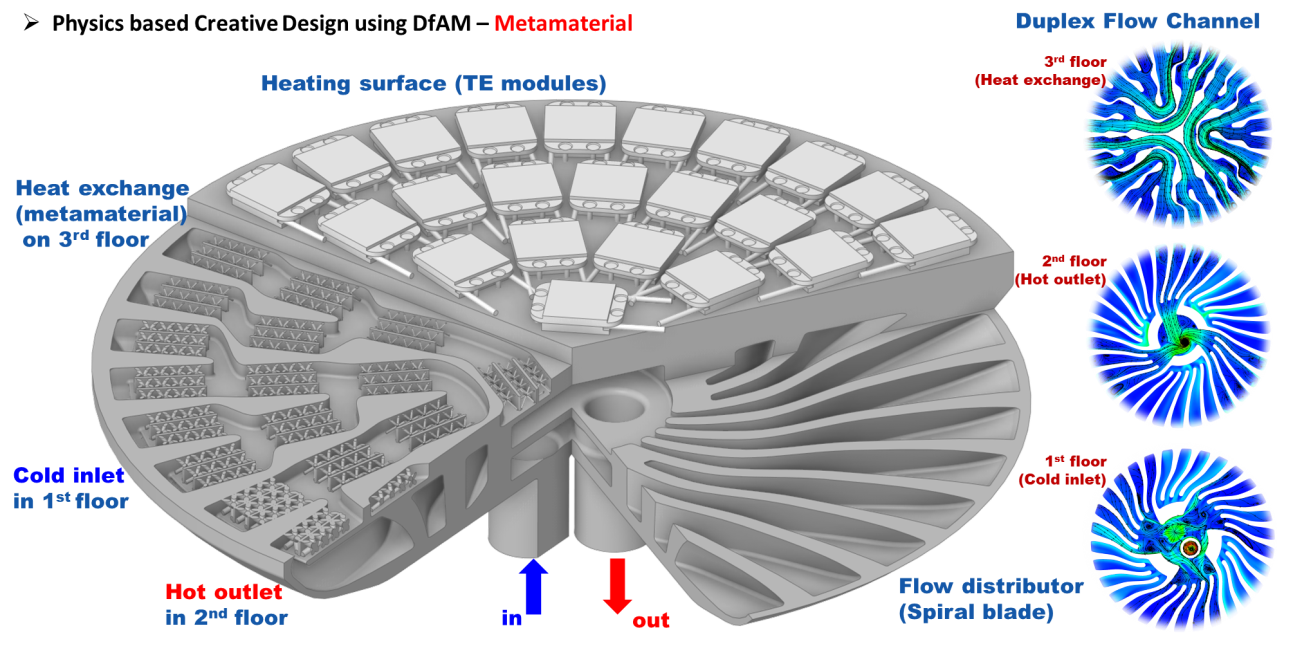

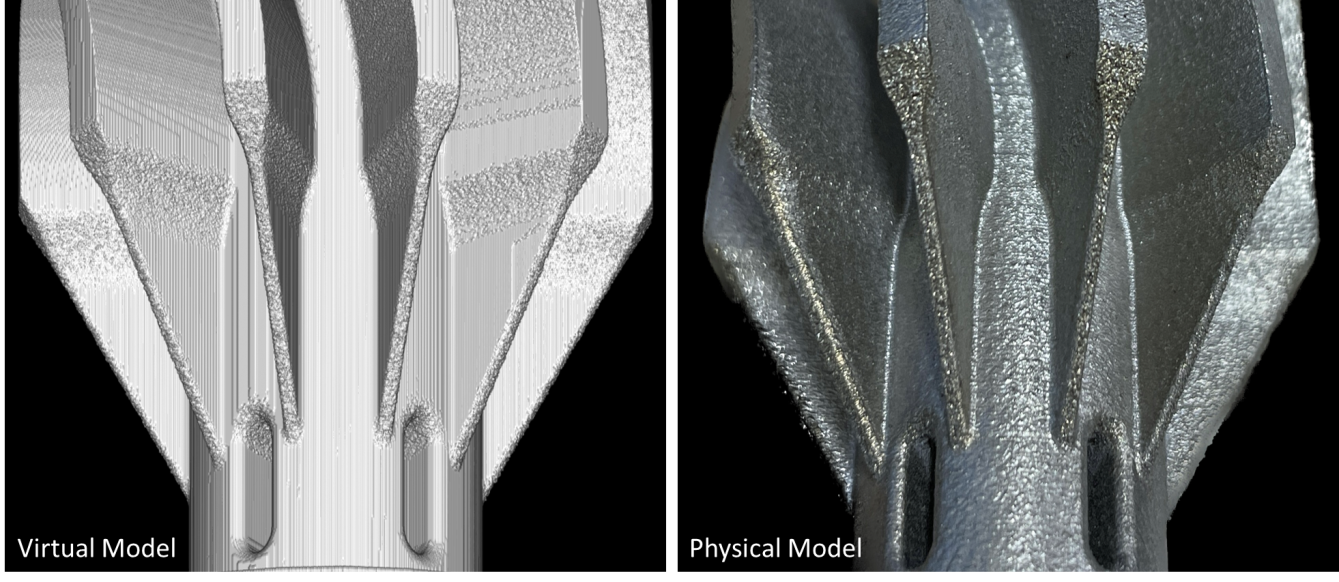

Recently, the center has focused on creative designs that maximize the functionality and efficiency of 3D printing through specialized design approaches. To achieve this, research is being conducted on digital manufacturing processes that can implement these innovative designs. The center is also developing optimization and predictive processes using multi-physics simulation technology applicable to the entire 3D printing manufacturing process. Ultimately, they aim to contribute to the expansion of 3D printing technology by developing virtual additive manufacturing technology that allows for the simulation and feasibility verification of 3D printing in a virtual environment.

Daegu-Gyeongbuk Center Technical Support Contact

Case stuides

Gas turbine combustion chamber components

Equipment : L-PBF

DfAM-based cooling optimization for semiconductor test chucks

Equipment : NTOP, FLUENT

Virtual additive manufacturing software

Equipment : In-house development