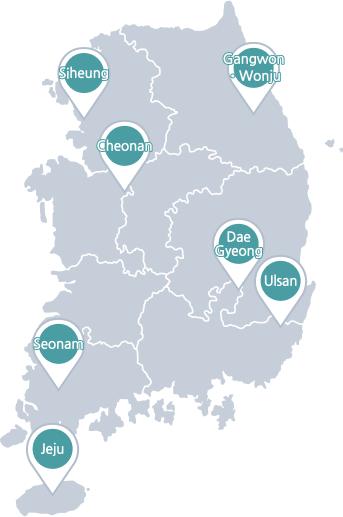

Staco recently opened an advanced AM research center and production facility in Siheung,

strengthens its capability for producing high-value aerospace and semiconductor components

through an MOU with KITECH

On October 8, 2024, Starco Co., Ltd. signed a Memorandum of Understanding (MOU) with the Korea Institute of Industrial Technology’s Siheung 3D Printing Manufacturing Innovation Center(KAMIC).

The signing ceremony was attended by key figures, including Taehoon Choi, Director of KITECH’s Intelligent Manufacturing Technology Lab, Son Yong, Director of the 3D Printing Manufacturing Innovation Center, Staco’s CEO Sangdon Byun, and other stakeholders. Staco recently relocated its advanced additive manufacturing research center and production facility to Siheung, Gyeonggi Province, aiming to strengthen its capabilities in producing high-value components for the aerospace, semiconductor, and defense industries. This MOU aims to leverage the 3D printing expertise of both parties to develop large-scale 3D printing process technology and promote the exchange of information and human resources related to 3D printing. KAMIC supports the industrial 3D printing sector through a comprehensive component validation support program, ensuring the quality of 3D-printed parts suitable for industrial applications, from sample testing to on-site evaluations.

![[Event] Staco Ltd. and KITECH Sign MOU for Large-Scale Metal AM in Aerospace, Semiconductor 3 20241008 104958 e1728616101313](https://kamic.or.kr/wp-content/uploads/2024/10/20241008_104958-e1728616101313.jpg)

The company plans to utilize large-scale metal 3D printers, including the XLine 2000R from Colibrium Additive (formerly GE Additive), to produce rocket engine components from superalloy Inconel 718.

Taehoon Choi expressed optimism about the collaboration, stating, “This partnership will be a crucial opportunity for Starco to establish a customized mass production system through additive manufacturing technology and contribute to the creation of high-value products in Korea’s manufacturing sector.”

Sangdon Byun, CEO of Staco, added, “In the past, it was challenging for SMEs to develop new high-value products, but with the advancement of additive manufacturing, this has become possible. We will do our best to develop and commercialize additive manufacturing technologies needed in industries such as aerospace and semiconductors.”

In addition to the MOU signing, an Additive Manufacturing Industrialization Seminar was held, followed by the opening ceremony of Starco’s corporate R&D center. The seminar featured presentations on topics such as data-driven 3D printing process optimization (by Son Yong, Director of KAMIC’s 3D Printing Manufacturing Innovation Center), industrialization of plasma powder for additive manufacturing (by Frederic Larouche, CEO of AP&C), and the commercialization of binder jet technology (by Il-yong Jung, Director at Colibrium Additive Korea).

After the seminar, participants toured the newly established Staco research facility, which garnered significant interest from attendees.

![[Event] Staco Ltd. and KITECH Sign MOU for Large-Scale Metal AM in Aerospace, Semiconductor 4 스타코MOU](https://kamic.or.kr/wp-content/uploads/2024/10/스타코MOU.gif)

![[Event] Staco Ltd. and KITECH Sign MOU for Large-Scale Metal AM in Aerospace, Semiconductor 5 스타코MOU2 1](https://kamic.or.kr/wp-content/uploads/2024/10/스타코MOU2-1.gif)

![[Event] Staco Ltd. and KITECH Sign MOU for Large-Scale Metal AM in Aerospace, Semiconductor 6 1728555112952 e1728618268616](https://kamic.or.kr/wp-content/uploads/2024/10/1728555112952-e1728618268616.jpeg)

[관련링크]

신소재경제 – ㈜스타코-생기원, 3D프린팅 기술개발 협력 MOU

![[Event] Staco Ltd. and KITECH Sign MOU for Large-Scale Metal AM in Aerospace, Semiconductor 1 20241008 103641 e1728615946870](https://kamic.or.kr/wp-content/uploads/2024/10/20241008_103641-e1728615946870.jpg)

![[Event] Staco Ltd. and KITECH Sign MOU for Large-Scale Metal AM in Aerospace, Semiconductor 2 스타코MOU3](https://kamic.or.kr/wp-content/uploads/2024/10/스타코MOU3.gif)